The SUPERMAXI: TOKOLOSH VII

Designed by New Zealander Brett Bakewell-White and Simonis Voogd Yacht Design Studio, she was the seventh yacht of the Big Boat Racing Team which made history winning the Sydney to Hobart race in 2000 and 2004, on top of winning the Maxi One design World Championships in 1996 (preliminary) 1997 and 1999, besides numerous other regatta and race wins as well as World Records under the sponsorships of Nicorette and Skandia, among others.

TOKOLOSH VII was built using a carbon fibre/Nomex sandwich construction, where the Nomex is the filling with carbon fibre skins as the “bread” on either side. The Nomex is a foam core of between 25 and 40 mm thickness, and the carbon fibre skins are impregnated with epoxy resin, which also binds them to the core.

The structures are then packed in a plastic film and 'cooked' under vacuum to eliminate air voids and consolidate the laminate. This involves putting the entire boat in an oven to bake it, which allows complete curing of the epoxy matrix.

Carbon fibre combines two important properties that are critical to racing yacht construction, light weight and great strength. When new, Nicorette VI’s completed hull only weighed 10 tons, with a further 10 tons in the keel. At the time this was a major weight saving compared to other similar yachts.

The hull was built with extra strength in the bow sections, because of the impact and extra loads this part of the boat experiences when powering through waves. Additional safety features in the construction of the bow include the use of Kevlar in the laminates to provide greater impact resistance, in case of collision with a floating object.

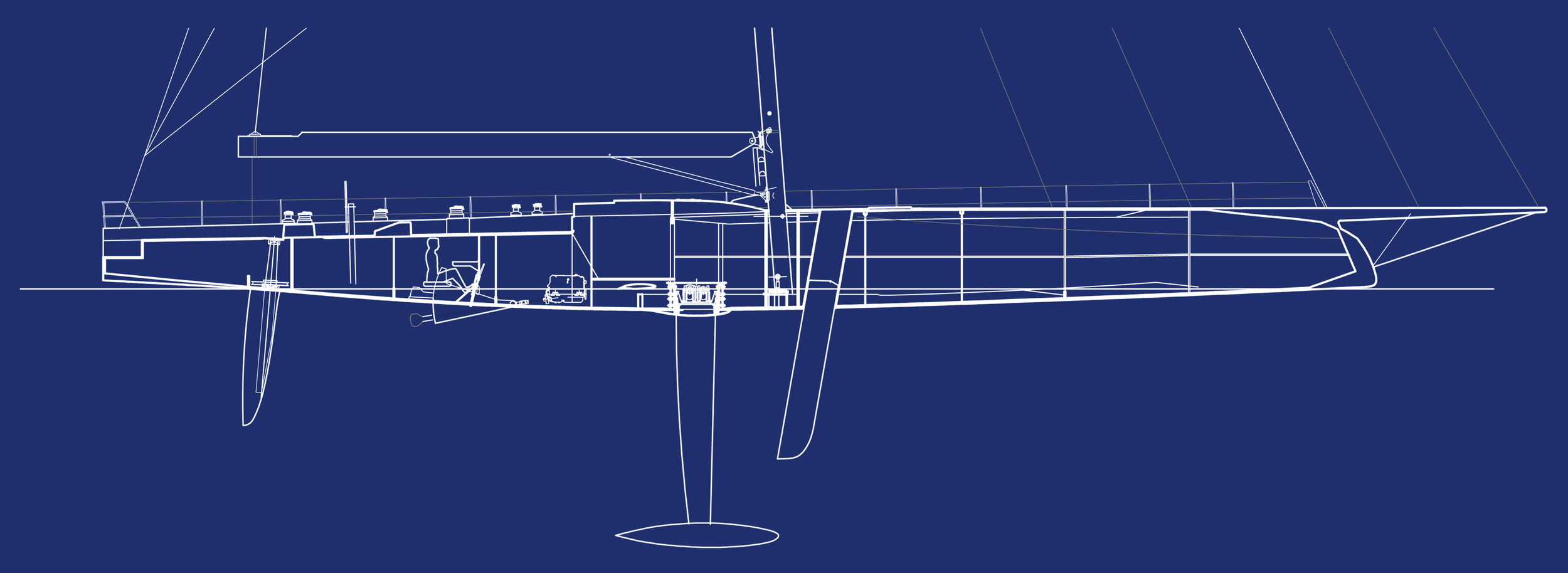

In 2004 the team developed a new canting keel technology, so when the boat had one installed, it was new to this genre of racing yacht.

Monohull racing yachts are designed to be at their most efficient when only slightly heeled, so stability is critical to the performance of a yacht. By being able to swing the keel out to the windward side of the hull, the stability is greatly increased.

The keel is canted up to 57 degrees either way by two powerful hydraulic rams inside the yacht which control the angle of the keel, each ram is capable of applying 120 tons of push or pull to swing the keel into its optimal angle. To put it another way, they are capable of lifting 240 tons, a weight 12 times that of the yacht.

TRANSFORMATION & REBUILD

The development of TOKOLOSH VII was based on TOKOLOSH VI, the competitive 90 footer which under the name Nicorette won the 2004 Rolex Sydney to Hobart Race as NICORETTE and parts of that yacht were used to shorten building time and expense.

The original design concept was by Dutch naval architect Alex Simonis, but the new super maxi owes much to the design talents of New Zealander Brett Bakewell-White.

The new version is unrecognisable from TOKOLOSH VI though parts of the original hull is still there.

The technical innovations that have been incorporated push the limits of present yacht design.

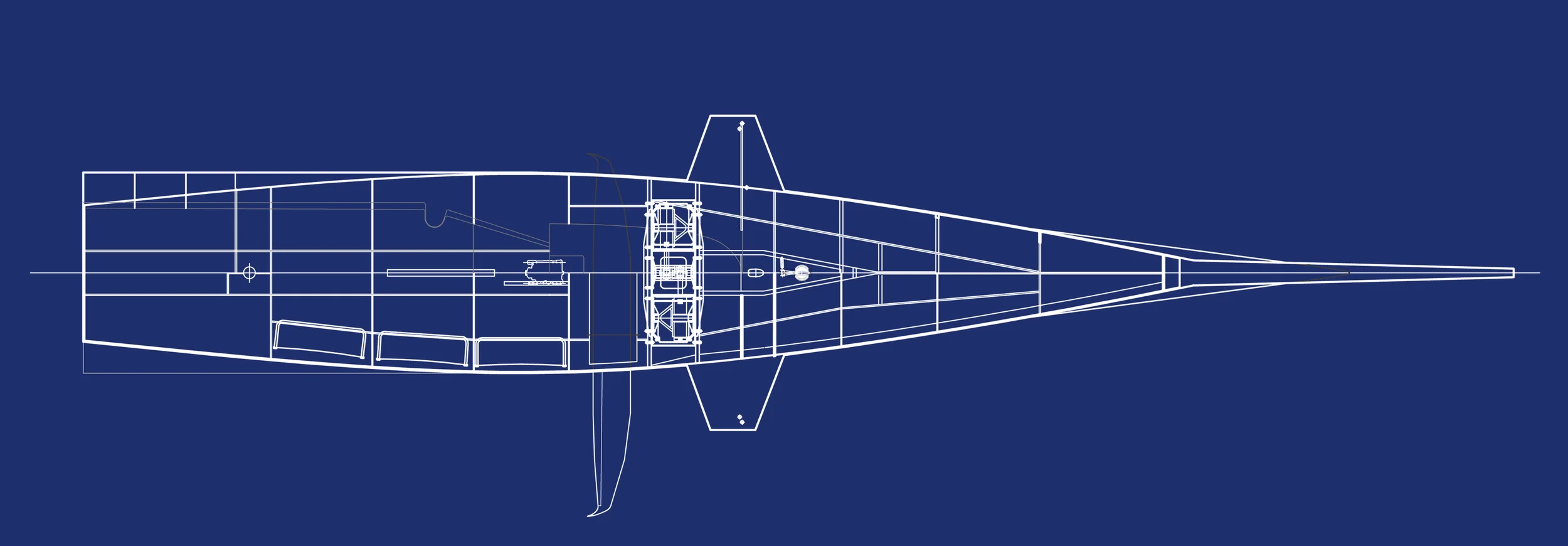

In order to lengthen the hull a portion of the bow was removed and then very carefully calculated V-shaped cuts were made into the hull so that it is strung apart, a bit like opening the fingers on your hand. The V-shaped indents into the hull were then filled with gussets and a new longer bow created.

In order not to have to create a whole new foredeck, a chamfer was then fitted to connect the new bow section of hull to the old deck. This has the benefit of creating a smoother flow of air across the foredeck and onto the headsail.

The radical look of the new forward sections of the boat is further enhanced by a reverse bow and a long bowsprit.

The canting keel TOKOLOSH yachts have always been relatively narrow boats and she remains so on the waterline. However, in order to support the much more powerful new rig the shroud base needed to be widened. In order to achieve this, a supporting structure has been put into the boat that is wider at deck level than the hull, so aerodynamic 'wings' have been created to contain the outer ends.

While wanting to retain the advantages of a narrow waterline all the way to the stern it became evident, through research conducted at the Yacht Research Institute at the University of Auckland, that for some of the new massive headsails that were planned, a wider sheeting angle would be critical. Hence the decision to run the maximum width all the way to the transom in the form of wing-like structures. An added benefit was also deemed to be the ability to maximize the use of crew weight for stability. Hence the motivation to create a wider platform at deck level.

All this has combined to produce a hull that looks radically different from any of the other super maxis. The most striking difference will be seen when comparing CQS with the winner of the last Sydney to Hobart race, Comanche.

The French designed Comanche can be seen to be heavily influenced by the IMOCA 60s that the Verdier Yacht Design and VPLP combination are so renowned for producing. The boat is wide, not just at deck level, but all the way to the waterline, and has been dubbed “the aircraft carrier” because of its huge flat deck area.

While TOKOLOSH VII is wide at deck level from the middle of the boat aft, her waterline is more of a cigar shape, this has a number of advantages when combined with the other technological advances that are being incorporated, because when heeled the hull in water is still symmetric.

DSS AQUA FOIL SYSTEM

Sailing boats rising out of the water on foils is not new. Sailors and designers have been experimenting with getting their craft to “break free”, or get “air time” for many decades. However, until very recently it was always small lightweight craft that were the test bed for these experiments and trials.

A keelboat does not lift its hull clear of the water like say a foiling moth, but the use of this technology can greatly increase the stability of a keelboat, and lift it a little, thereby reducing its displacement and wetted surface area, and therefore resistance.

TOKOLOSH VII has an adaptation of this feature, a DSS aqua foil system, installed and she is one of the biggest boats currently using this type of technology.

The system uses a sliding board that runs across the boat from one side to the other, and protrudes from the hull just below the waterline. The board is deployed on the leeward, or downwind, side of the boat to give lift and added stability. The hull, in effect, becomes like an aeroplane with one wing.

When the wind works on a monohull yacht’s sails it has two effects, one is for the boat to lean over, and the other is for it to move forward. With the foil deployed on the leeward side of the boat, as it moves forward, the board starts to act like an aeroplane wing, and tries to lift. The faster the boat goes, the more lift it gets from the foil, thereby reducing the amount that the boat leans over, and therefore making the rig and the hull more efficient.

In the case of TOKOLOSH VII, this technology is being combined with the already proven advantages of a canting keel. Brett Bakewell-White, who is the designer of the hull modifications said: “We think canting keel and aqua foil are complementary technologies; they enhance each other.”

With the aqua foil out one side and the canting keel out the other, the “aeroplane” now basically has two wings.

For a boat that is relatively narrow on the waterline, this double dose of righting moment is a material performance enhancer, and with the extra speed that this enhancement will deliver, the two wings will start to lift the boat, reducing the displacement and the wetted surface area. Result, more speed.

However, advantages like this don’t come without a cost. As Brett says, “If you increase righting moment you increase horsepower and you increase loads. You can add sail area and it doesn’t increase loads, the boat just tips over sooner. It’s righting moment that increases loads, not sail area.” There has consequently had to be a huge rethink on the engineering of the load bearing parts of the boat, hence the widening of the shroud base to give the mast more support.

All the boats that have so far tried a foil plank have been much smaller than TOKOLOSH VII, and not fast enough to make it work consistently when going to windward. It is hoped that the extra speed generated by a boat of 100 feet, will enable her to lift while close-hauled. This will be a breakthrough in keelboat sailing.

RIG & SAILS

While there are substantial modifications to the hull and some cutting edge technology in the underwater fins and foils, the engine of a sailing boat is the bit that sticks up in the air…the rig and sails. Like the rest of the package it must be efficient and of course powerful.

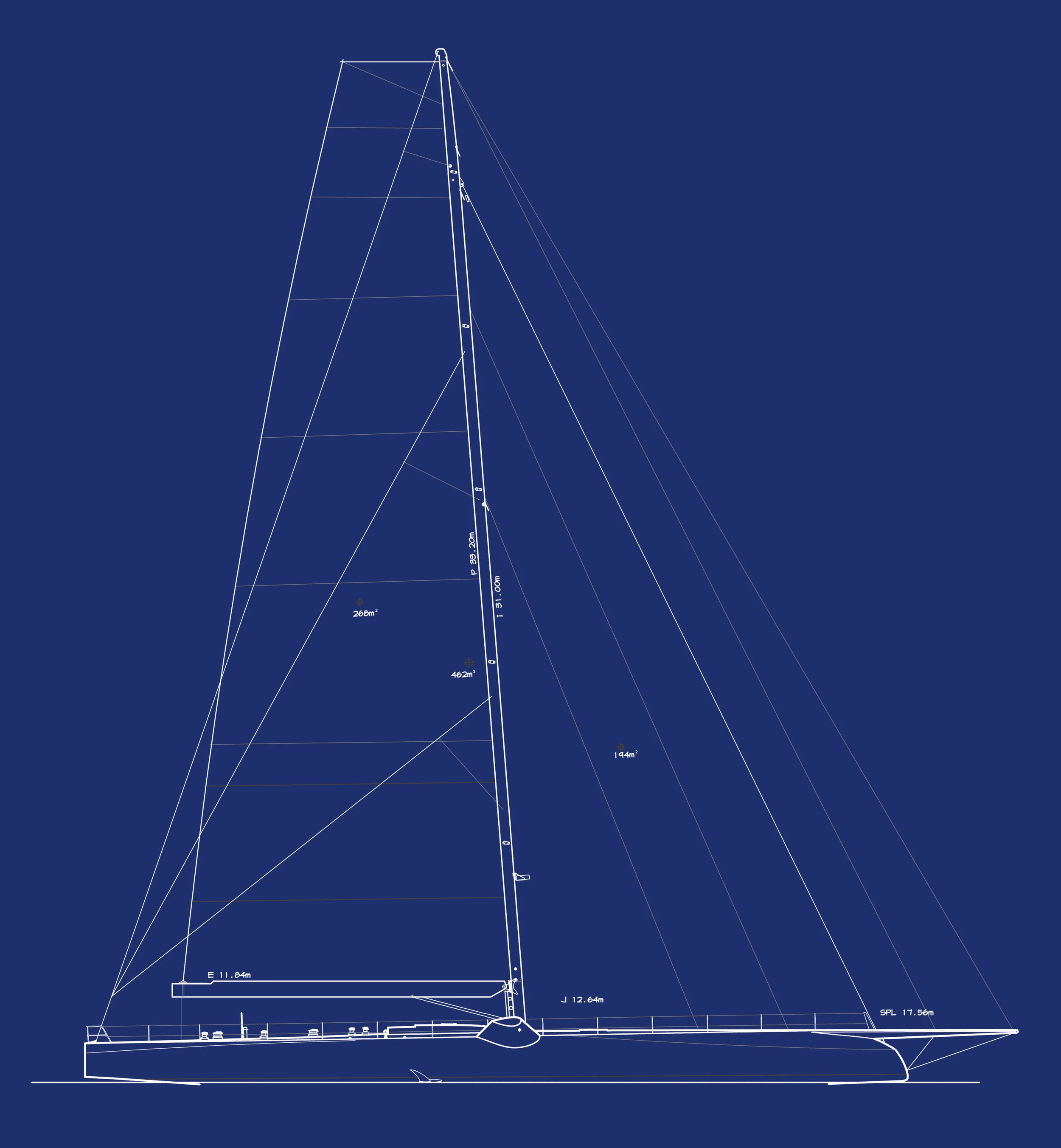

When designing the sail plan, Rodney Keenan of Evolution Sails in Auckland has had the advantage of using one of the best wind tunnels in the world. He worked closely with the rest of the team at Auckland University anddesigned a rig with a lot of horsepower to drive the yacht.

As with everyone involved in this project, Rodney has been surprised by the potential speed of the boat when testing computer created models. He said: “We’re looking at the sail package from a multi-hull perspective rather than a mono-hull perspective.”

The addition of the wide platform at the stern of the boat has been critical to the design package and it allows a wide enough sheeting angle to facilitate the use of some truly huge headsails. As well as conventional jibs, the boat carries a wide selection of staysails, which give many more sail combination options.

Explaining this Rodney said: “Big jibs are faster to accelerate, and you get more staysail. It’s also easier to have more configurations and more horsepower. It’s a far nicer way to change gears quickly.” Essentially, with a series of headsails the efficiency of the flow of air across the sails is improved by the slots between the sails, creating a venetian blind effect.

With the new longer bow, the rig is effectively further back in the boat, in line with the trend amongst other yachts of similar size. When the Australian boat Wild Oats re-configured before last year’s Sydney-to-Hobart race, they did the same thing, and Comanche from America was built this way too.

Back in the early 2000s, boats of this size had their masts about 40% to 42% back from the bow, but TOKOLOSH VII will have hers 46% to 47% back in the boat.

One of the problems that Rodney has encountered while designing the power-pack that is the rig and sails is the fact that, because an aqua foil wing is not believed to have been used on a boat of this size or been used in conjunction with a canting keel, no one is really sure what effect it will have on the centre of lateral resistance. Knowing this is critical to balancing the boat, through the position of the centre of effort; it is an integral part of the rig design.

Rodney is going for 4 degrees of mast rake, which is radical when you consider that the standard is about 1 degree. There is a margin for adjustment of about 1.5 degrees before it would be necessary to re-cut sails.

It may seem unlikely for a sailmaker to be trying to reduce the number of sails in the inventory, but one of the by-products of the speed that this boat is expected to generate is the need for a smaller number of sails. In simulated tests, the apparent wind angle never goes aft of the beam. “Even in 20 knots with a 150 true wind angle, the apparent is 68 degrees or something,” commented Rodney, “so you’re only just eased if you’re under jib. The apparent never went aft of 72 or 73 degrees.”

The weight of the sails carried is also a material performance factor. “With the sail package we’re trying to build a set of sails that allows us to have the minimum number of sails on board to reduce weight,” he explained. “If you come off the plane because you’re carrying one extra sail which is 100 kg, then you drop the performance by 16%. We’ll probably only carry seven sails, where other boats of this size will carry eleven or twelve. If we can get rid of 1,000kg of sails, that’s a huge weight saving.”

Naturally, all this sail area has to be held up by something. The mast, as well as being strong enough to take the huge loads involved, also needs to be aerodynamically efficient. We are fortunate that the mast we have is a good one as Rodney explains: “It is the original rig, but with new spreaders and some more carbon. The original was really nice; it’s a super high modulus carbon rig. We’re adding 50kg of carbon to the rig, and widening the stay base gives us the opportunity to put a lot more horsepower on it."